- 439 ROUTE 17 NORTH

- MAHWAH NJ, USA

- PHONE (888) SOCOMEC

- PHONE (888) 762-6632

- FAX (201) 584-0229

- Info@theEEIgroup.com

|

|

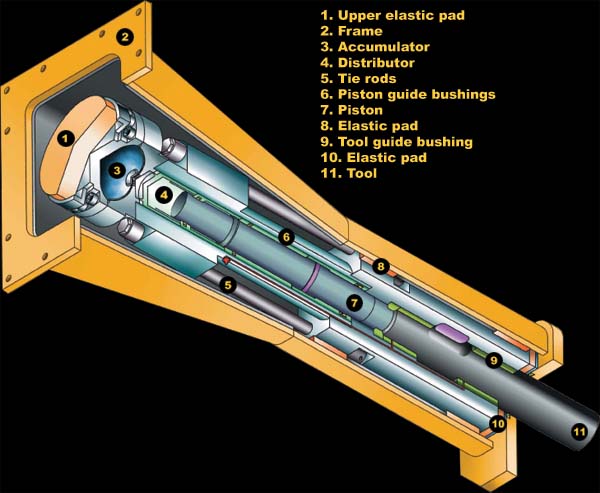

Piston design

SOCOMEC has designed a long stepped section piston which delivers a very powerful impact to the tool and assures the owner of the highest productivity.

Hydraulic brake

All SOCOMEC breakers have a hydraulic braking system which helps to eliminate blank strokes.

Tool gasket

A large wiper seal on the tool keeps dust out of the lower chamber and helps to keep grease inside the breaker. It also helps to reduce noise levels.

Cylinder guide bushes

In the SOCOMEC construction, the piston is not directly in contact with the cylinder but it slides in a series of guide bushings. When resealing is necessary it is possible to remove the piston and bushings without loosening the breaker tie-rods. This cost saving design is exclusive to SOCOMEC (series TS only).

Stroke variation

SOCOMEC breakers deliver the highest productivity in any material. This is achieved by variation of the blow frequency and impact energy. The breaker reacts to the resistance of the material to be broken and is designed to work always at maximum efficiency.

High capacity hydraulic accumulator

The SOCOMEC designed accumulator offers consistently high performance over a long period of time and assures a high degree of protection to the hydraulic system of the excavator.

Power greasing

It is possible to connect the breaker to a power greasing system, operated from the drivers cab. Kit available on request.

Sealing system

Three seal rings between the cylinder lining bushes and the piston and further seals between the lining bushes and the cylinder offer excellent protection from oil leaks. Low friction type seals are used which do not overheat and have a long service life.

Soundproofing

The innovative soundproofing system reduces noise by approximately 50%. This is achieved by using special guide and coating plates which completely isolate the breaker from its frame.

Under water operation

It is possible to use the breaker under water and for under ground mining. Please consult your dealer for instructions.

Energy recovery

Thanks to the piston recoil energy, some of the oil already used is directed back to the pressure chamber and is spent on the next stroke. This system increases the breaker power and productivity without drawing further energy from the excavator.

Double damping system

Perfect hydraulic balance of the moving parts so as to avoid all possible breaker recoils. Shock absorbers are built into the breaker frame above and below the breaker to avoid transmitting micro vibrations to the excavator arm.

| Breaker Type | Maximum Frequency | Maximum Oil Flow | Maximum Working Pressure | Breaker Weight In Working Condition | Tool Diameter | Height Of Breaker With Tool w/o Plate | Minimum Width | Max Exhaust Back Pressure | To Be Mounted On Excavators |

| b/min | gal/min | psi | lbs | inches | inches | inches | psi | lbs | |

| MDO 1000 TS | 600 - 800 | 45 | 1900 | 2200 | 4.4 | 84 | 12 x 13 | 145 | From 26000 to 32000 |

| MDO 1300 TS | 500 - 680 | 38 | 1900 | 2860 | 4.7 | 93 | 12.4 x 14.6 | 145 | From 30000 to 44000 |

| MDO 1700 TS | 480 - 650 | 50 | 2000 | 3740 | 5.3 | 102 | 14.4 x 15.3 | 144 | From 38000 to 54000 |

| MDO 2300 TS | 460 - 630 | 59 | 2000 | 5000 | 6.0 | 110 | 15.8 x 16.9 | 145 | From 50000 to 66000 |

| MDO 3000 TS | 380 - 500 | 72 | 2150 | 6600 | 6.5 | 119 | 17 x 19.2 | 145 | From 66000 to 100000 |

| MDO 4000 TS | 360 - 480 | 88 | 2300 | 9240 | 7.1 | 126 | 20 x 25.5 | 145 | From 99000 to 165000 |

| TS = Stroke variation and energy recovery | |||||||||

Thanks to more than 30 years of constant work, investments in research and technological developments, Socomec hydraulic breakers are now the most innovative and reliable in their own field. The standing leadership in the Italian market and the increasing acquisitions of new markets abroad are the best witness to technical and commercial achievemnts on account of which Socomec is today ranging top in the worldwide production of hydraulic breakers. A severe quality control of the output processes, from manufacturing to assembly and to delivery of the finished product to the customer, has enabled Socomec to take the challenges of the new millennium as just as many new and ambitious goals. Since more than four years, Socomec has been awarded the ISO 9002 certification, which is now committed to turn into the prestigious VISION 2000 certification – a further guarantee of the high quality of its product.

Thanks to more than 30 years of constant work, investments in research and technological developments, Socomec hydraulic breakers are now the most innovative and reliable in their own field. The standing leadership in the Italian market and the increasing acquisitions of new markets abroad are the best witness to technical and commercial achievemnts on account of which Socomec is today ranging top in the worldwide production of hydraulic breakers. A severe quality control of the output processes, from manufacturing to assembly and to delivery of the finished product to the customer, has enabled Socomec to take the challenges of the new millennium as just as many new and ambitious goals. Since more than four years, Socomec has been awarded the ISO 9002 certification, which is now committed to turn into the prestigious VISION 2000 certification – a further guarantee of the high quality of its product.