- 439 ROUTE 17 NORTH

- MAHWAH NJ, USA

- PHONE (888) SOCOMEC

- PHONE (888) 762-6632

- FAX (201) 584-0229

- Info@theEEIgroup.com

|

|

TECHNICAL FEATURES

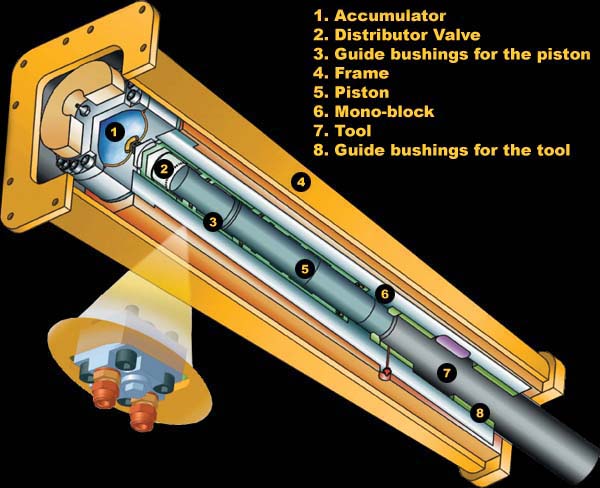

The new DMS breakers are built in a monoblock structure, eliminating the traditional tie-rod bolts.

The only one part which has to be assembled to the body of the breaker by using screws is the accumulator.

The accumulator has a secondary function as a cap, sealing the top of the breaker.

The elimination of tie-rod bolts from the breaker also eliminates the most common cause of downtime, broken bolts.

Moreover the serious consequences of using a breaker with an undetected broken bolt are eliminated.

Service operations are very easy and economical. By simply removing the accumulator, all bushings and the piston are immediately accessible.

SILENCED VERSION

The monoblock structure is vulcanized in a unique body with the external case by means of a polyurethane solution.

The unique stepped piston design delivers maximum energy to the chisel and minimum recoil to the breaker body.

The DMS breakers have an advanced modular hydraulic brake. When the tool is not in contact with the rock the oil supply is automatically recycled and pressure strokes are avoided.

A special valve stabilizes the working pressure no matter what the oil flow is. In that way it keeps the energy stroke constant.

|

| Breaker Type | Maximum Frequency | Maximum Oil Flow | Maximum Working Pressure | Breaker Weight In Working Condition | Tool Diameter | Height Of Breaker With Tool w/o Plate | Minimum Width | Max Exhaust Back Pressure | To Be Mounted On Excavators |

| b/min | gal/min | psi | lbs | inches | inches | inches | psi | lbs | |

| DMS 50 | 1200 | 6.6 | 1750 | 132 | 1.5 | 29.5 | 4.9 | 290/435 | From 1500 to 2650 |

| DMS 95 | 1200 | 9.3 | 1750 | 209 | 1.8 | 40 | 5.3 | 290/435 | From 2650 to 4000 |

| DMS 165 | 1200 | 12 | 1750 | 363 | 2.2 | 43.3 | 6.1 | 290/435 | From 4000 to 6600 |

| DMS 210 | 1100 | 16 | 1750 | 463 | 2.5 | 51.2 | 6.9 | 290/435 | From 6100 to 8350 |

| DMS 260 | 1000 | 21.2 | 1750 | 573 | 2.7 | 53.1 | 7.3 | 290/435 | From 8350 to 12100 |

| DMS 310 | 1000 | 26.6 | 1750 | 683 | 2.9 | 55.7 | 7.5 | 360 | From 11000 to 15500 |

| DMS 410 | 900 | 29.2 | 1750 | 904 | 3.1 | 63 | 8.3 | 360 | From 14350 to 20900 |

| DMS 530 | 900 | 32.3 | 1750 | 1166 | 3.3 | 69.6 | 10 | 360 | From 17650 to 25350 |

| DMS 850 | 900 | 34.6 | 1750 | 1870 | 3.7 | 72.5 | 10.2 | 360 | From 20900 to 29750 |

Thanks to more than 30 years of constant work, investments in research and technological developments, Socomec hydraulic breakers are now the most innovative and reliable in their own field. The standing leadership in the Italian market and the increasing acquisitions of new markets abroad are the best witness to technical and commercial achievemnts on account of which Socomec is today ranging top in the worldwide production of hydraulic breakers. A severe quality control of the output processes, from manufacturing to assembly and to delivery of the finished product to the customer, has enabled Socomec to take the challenges of the new millennium as just as many new and ambitious goals. Since more than four years, Socomec has been awarded the ISO 9002 certification, which is now committed to turn into the prestigious VISION 2000 certification – a further guarantee of the high quality of its product.

Thanks to more than 30 years of constant work, investments in research and technological developments, Socomec hydraulic breakers are now the most innovative and reliable in their own field. The standing leadership in the Italian market and the increasing acquisitions of new markets abroad are the best witness to technical and commercial achievemnts on account of which Socomec is today ranging top in the worldwide production of hydraulic breakers. A severe quality control of the output processes, from manufacturing to assembly and to delivery of the finished product to the customer, has enabled Socomec to take the challenges of the new millennium as just as many new and ambitious goals. Since more than four years, Socomec has been awarded the ISO 9002 certification, which is now committed to turn into the prestigious VISION 2000 certification – a further guarantee of the high quality of its product.